- Home

- Product Naming

- Motors

- Lab Instrument

- Application and Service

- Services

- Blog

180 series explosion-proof permanent magnet motor

Wheatstone

| Availability: | |

|---|---|

| Quantity: | |

Product Description

180 Series Explosion-Proof Permanent Magnet Motors

Product Overview

The WHEATSTONE 180 Series Explosion-Proof Permanent Magnet Motors are designed for hazardous industrial environments where explosive gases, vapors, or dusts may be present. Featuring advanced permanent magnet technology combined with robust explosion-proof construction, these motors ensure high efficiency, compact size, and superior reliability while maintaining compliance with global safety standards such as IECEx, ATEX, and China’s Ex certifications.

These motors are ideal for applications where precise control, high power density, and energy efficiency are critical, especially in industries such as oil & gas, chemical processing, mining, and hazardous material handling.

Key Features

Explosion-Proof Safety – Flameproof enclosure prevents ignition of explosive atmospheres, meeting Ex d IIB T4 Gb or equivalent classifications.

High Efficiency Design – Permanent magnet excitation reduces copper losses and improves energy efficiency.

Compact and Lightweight – Smaller frame size with higher power density compared to conventional induction motors.

Wide Speed Control Range – Stable performance across variable load and speed conditions.

Rugged Durability – High-strength housing, anti-corrosion treatment, and reinforced insulation for harsh operating environments.

Low Maintenance – Permanent magnet structure minimizes wear components, reducing servicing needs.

Technical Highlights

Motor Type: Permanent Magnet Synchronous Motor (PMSM)

Series: 180 Explosion-Proof Series

Frame Size:180 mm

Rated Voltage: 220V / 380V / Custom options

Power Range: 50W – 1.5kW (customizable)

Speed Range: 300 – 5000 rpm

Insulation Class: F or H

Protection Level: IP65 – IP67

Cooling Method: Natural cooling (IC410) or forced cooling (IC416) available

Applications: Oil and gas equipment, chemical plants, mining machinery, hazardous conveyors, and automation systems

Motor Model

| Motor Model | L(mm) |

| 180ST-□150XX-EX-XXV(J) | 264 |

| 180ST-□190XX-EX-XXV(J) | 285 |

| 180ST-□250XX-EX-XXV(J) | 302 |

| 180ST-□300XX-EX-XXV(J) | 319 |

| 180ST-□360XX-EX-XXV(J) | 340 |

| 180ST-□420XX-EX-XXV(J) | 357 |

| 180ST-□500XX-EX-XXV(J) | 374 |

| 180ST-□700XX-EX-XXV(J) | 412 |

| 180ST-□150XXB-EX-XXV(J) | 371 |

| 180ST-□190XXB-EX-XXV(J) | 392 |

| 180ST-□250XXB-EX-XXV(J) | 409 |

| 180ST-□300XXB-EX-XXV(J) | 426 |

| 180ST-□360XXB-EX-XXV(J) | 447 |

| 180ST-□420XXB-EX-XXV(J) | 464 |

| 180ST-□500XXB-EX-XXV(J) | 481 |

| 180ST-□700XXB-EX-XXV(J) | 519 |

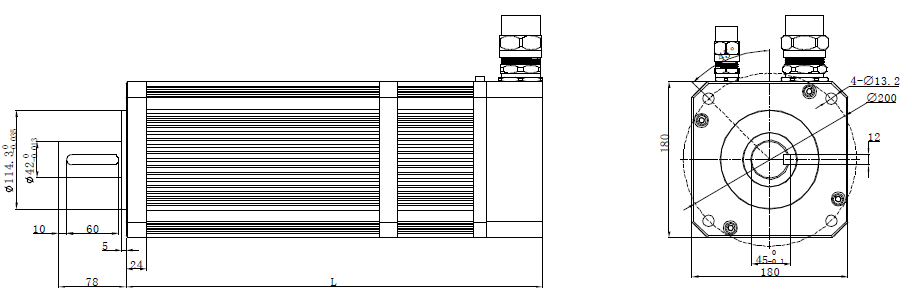

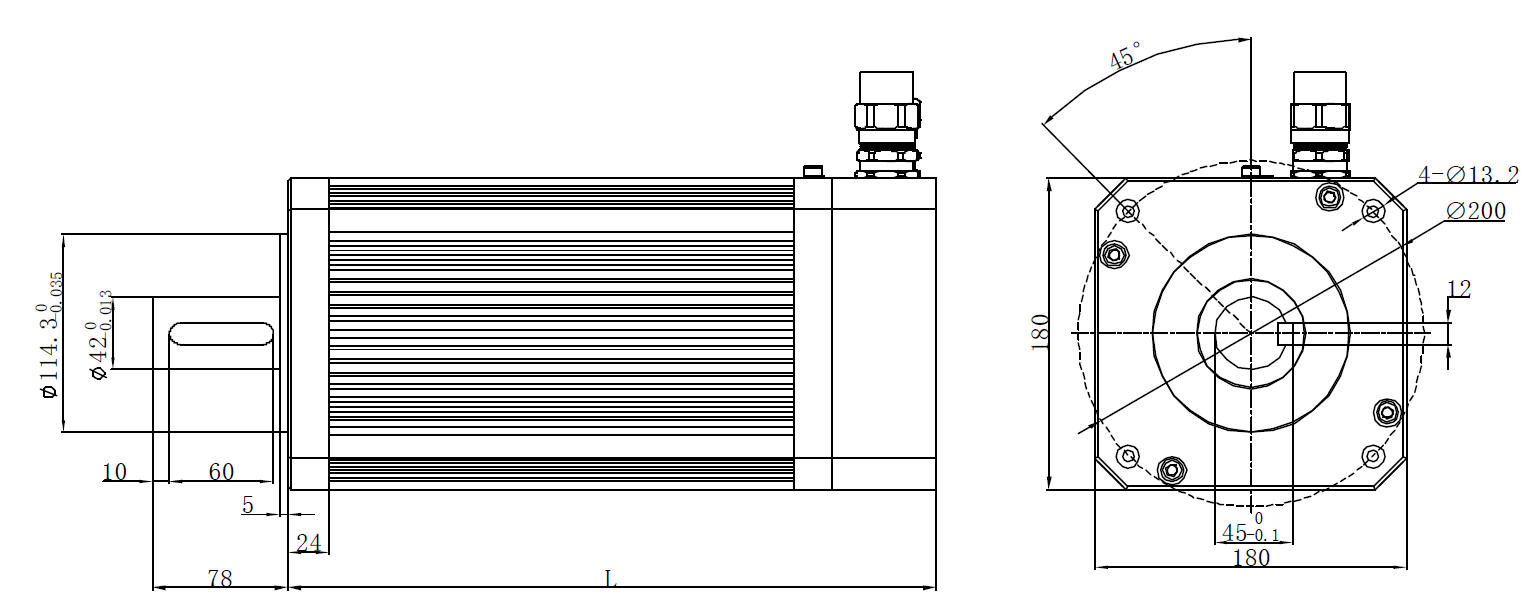

Motor Dimensions

180 Explosion-Proof Permanent Magnet Motor with Brake

180 Explosion-Proof Permanent Magnet Motor Without Brake

Electrical Parameters

| Main performance parameters | ||||

| Motor Model | 180ST-口16030-EX | 180ST-口19030-EX | 180ST-口25030-EX | 180ST-口30030-EX |

| Rated Power(KW) | 5.0 | 6.0 | 7.5 | 9.0 |

| Rated current(A) | 22.0 | 27.0 | 33.0 | 40.0 |

| Rated speed(RPM) | 3000 | 3000 | 3000 | 3000 |

| Maximum speed(RPM) | 3600 | 3600 | 3600 | 3600 |

| Rated Torque(NM) | 16.0 | 19.0 | 25.0 | 30.0 |

| Maximum Torque(NM) | 40.0 | 47.5 | 62.5 | 75.0 |

| Rotor of Inertia(kg.cm²) | 32.6 | 45.0 | 55.1 | 65.2 |

| Main performance parameters | |||

| Motor Model | 180ST-口36030-EX | 180ST-口42030-EX | 180ST-口50030-EX |

| Rated Power(KW) | 11.0 | 13.0 | 15.0 |

| Rated current(A) | 49.0 | 58.0 | 67.0 |

| Rated speed(RPM) | 3000 | 3000 | 3000 |

| Maximum speed(RPM) | 3600 | 3600 | 3600 |

| Rated Torque(NM) | 36.0 | 42.0 | 50.0 |

| Maximum Torque(NM) | 72.0 | 84.0 | 100.0 |

| Rotor of Inertia(kg.cm²) | 77.5 | 87.7 | 97.8 |

| Main performance parameters | ||||

| Motor Model | 180ST-口16030-EX-380V | 180ST-口19030-EX-380V | 180ST-口25030-EX-380V | 180ST-口30030-EX-380V |

| Rated Power(KW) | 5.0 | 6.0 | 7.5 | 9.0 |

| Rated current(A) | 13.0 | 15.0 | 19.0 | 23.0 |

| Rated speed(RPM) | 3000 | 3000 | 3000 | 3000 |

| Maximum speed(RPM) | 3600 | 3600 | 3600 | 3600 |

| Rated Torque(NM) | 16.0 | 19.0 | 25.0 | 30.0 |

| Maximum Torque(NM) | 40.0 | 47.5 | 62.5 | 75.0 |

| Rotor of Inertia(kg.cm²) | 32.6 | 45.0 | 55.1 | 65.2 |

| Main performance parameters | |||

| Motor Model | 180ST-口36030-EX-380V | 180ST-口42030-EX-380V | 180ST-口50030-EX-380V |

| Rated Power(KW) | 11.0 | 13.0 | 15.0 |

| Rated current(A) | 28.0 | 33.0 | 38.0 |

| Rated speed(RPM) | 3000 | 3000 | 3000 |

| Maximum speed(RPM) | 3600 | 3600 | 3600 |

| Rated Torque(NM) | 36.0 | 42.0 | 50.0 |

| Maximum Torque(NM) | 72.0 | 84.0 | 100.0 |

| Rotor of Inertia(kg.cm²) | 77.5 | 87.7 | 97.8 |

FAQ

Q1: What industries typically use the 180 Series Explosion-Proof Permanent Magnet Motor?

A1: This motor is widely applied in oil & gas, chemical processing, mining, coal industries, hazardous material handling, and other explosive environments where safety and reliability are critical.

Q2: What explosion-proof standards does this motor comply with?

A2: The motor meets IECEx, ATEX, and China Ex standards, typically classified as Ex d IIB T4 Gb, ensuring it can safely operate in explosive gas or dust environments.

Q3: What are the advantages of using a permanent magnet motor in explosion-proof applications?

A3: Permanent magnet motors provide higher efficiency, lower energy loss, compact size, higher torque density, and reduced maintenance, making them more suitable for demanding hazardous environments compared to conventional induction motors.

Q4: What is the typical power and speed range of the 180 Series?

A4: The 180 Series supports power ratings from 2 kW up to 15 kW, with a speed range of 300–3000 rpm (customizable for special applications).

Q5: What cooling methods are available?

A5: The motor can be configured with natural cooling (IC411) or forced cooling (IC416), and optional oil or water cooling for continuous heavy-duty operations.

Q6: Can the 180 Series Explosion-Proof Permanent Magnet Motor be customized?

A6: Yes. WHEATSTONE offers custom voltage, shaft design, mounting options, feedback devices, and cooling systems to meet customer-specific requirements.

Q7: What protection levels are provided?

A7: Standard protection is IP55–IP65, ensuring reliable performance against dust and water ingress in harsh environments.